뉴스

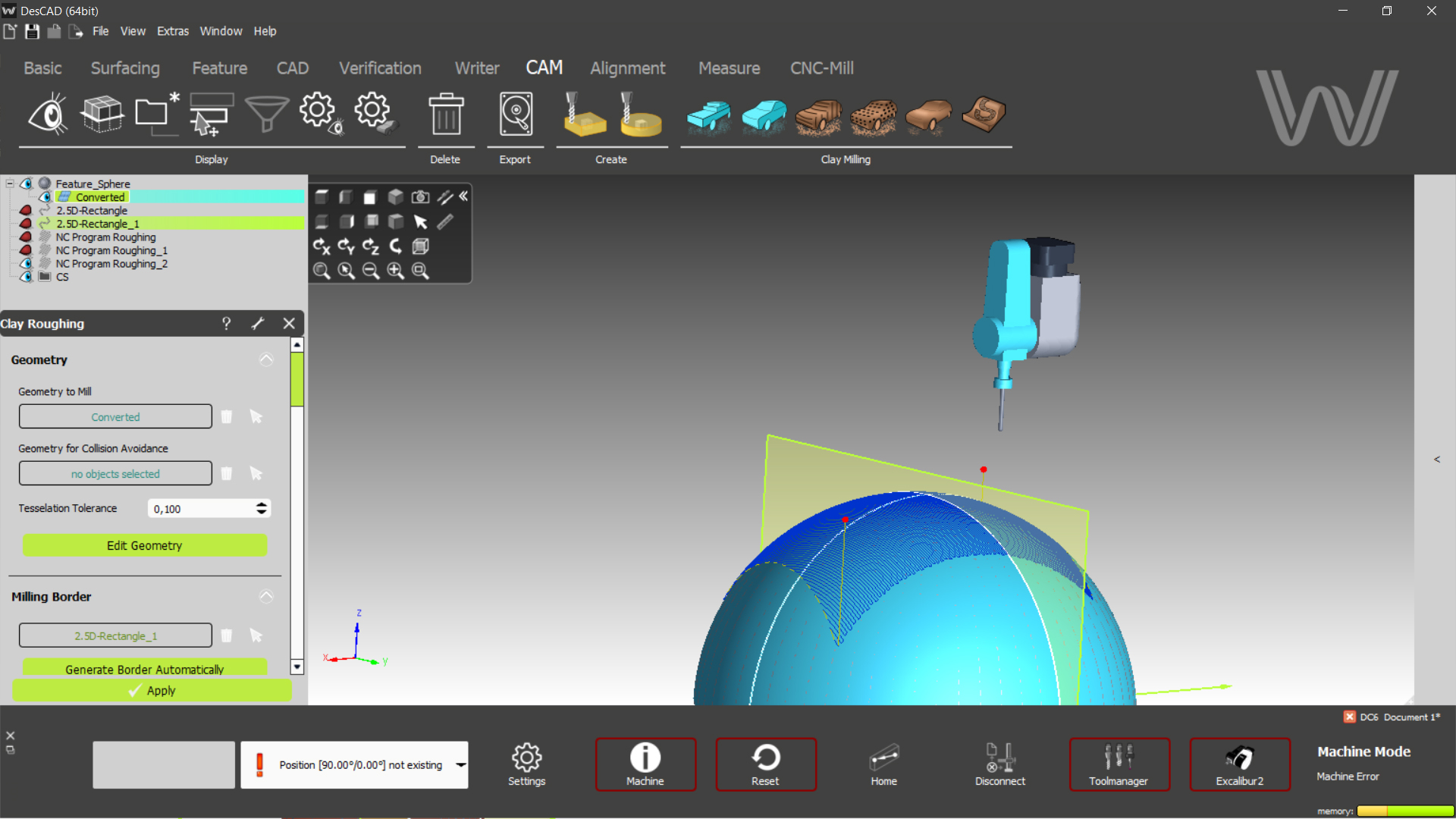

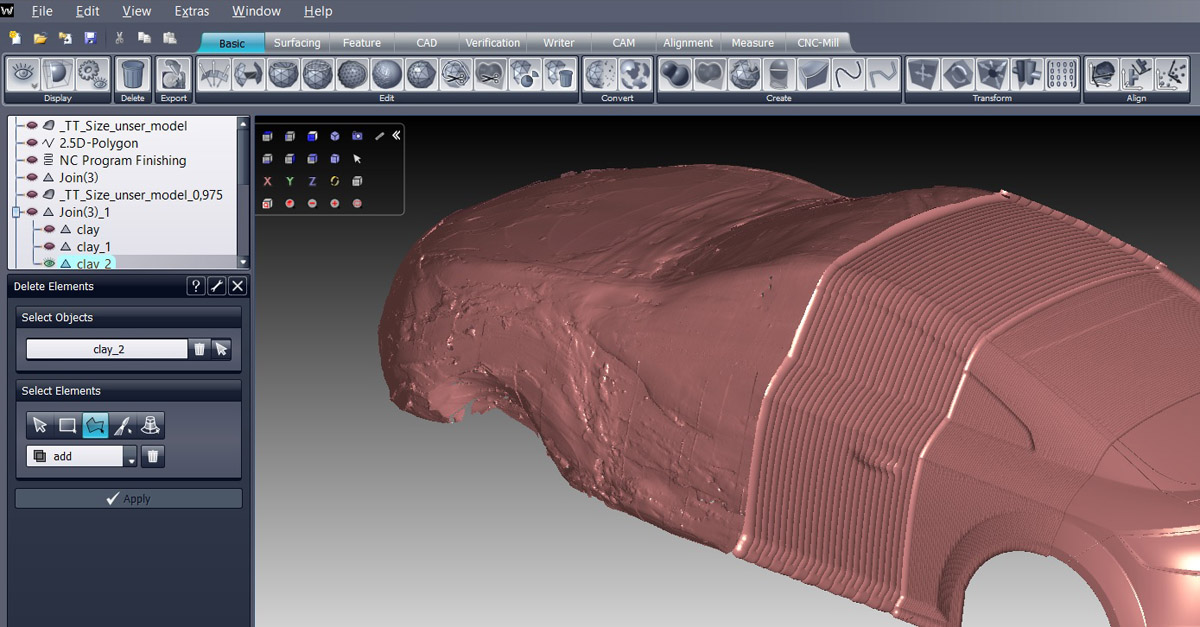

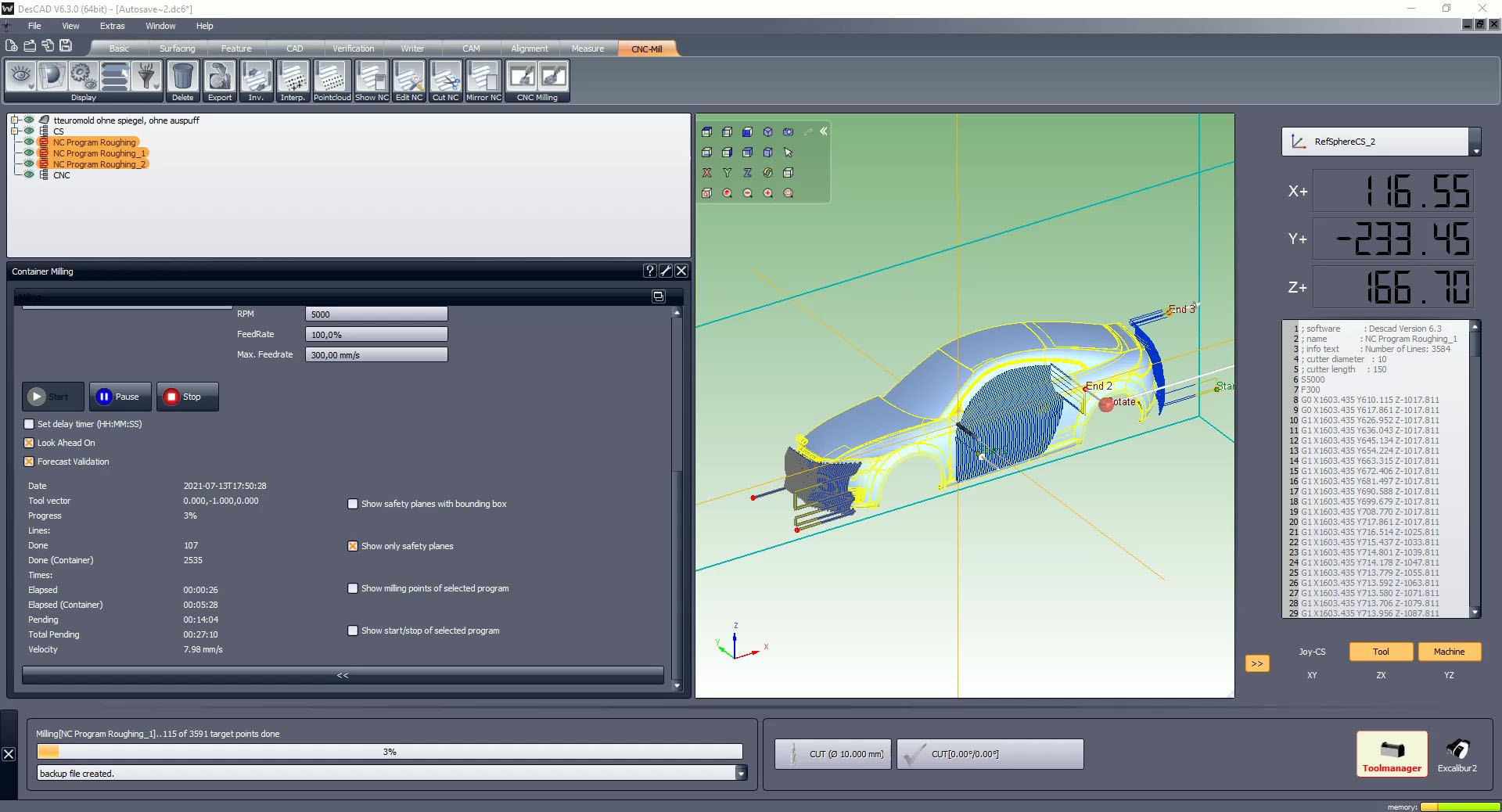

Functions you really need for clay milling in a car design studio, easy handling and an intuitive interface which is made for clay modellers and not only milling experts: that´s what sets Des

We focus completely on clay modellers and milling of clay and hardboard in design studios. With an own in-house software development team we create a software that is tailor-made for the needs of our customers. No fuss – only functions you really need. So this is NOT a software that was developed and is mainly sold to metal millers – this is for you clay guys.

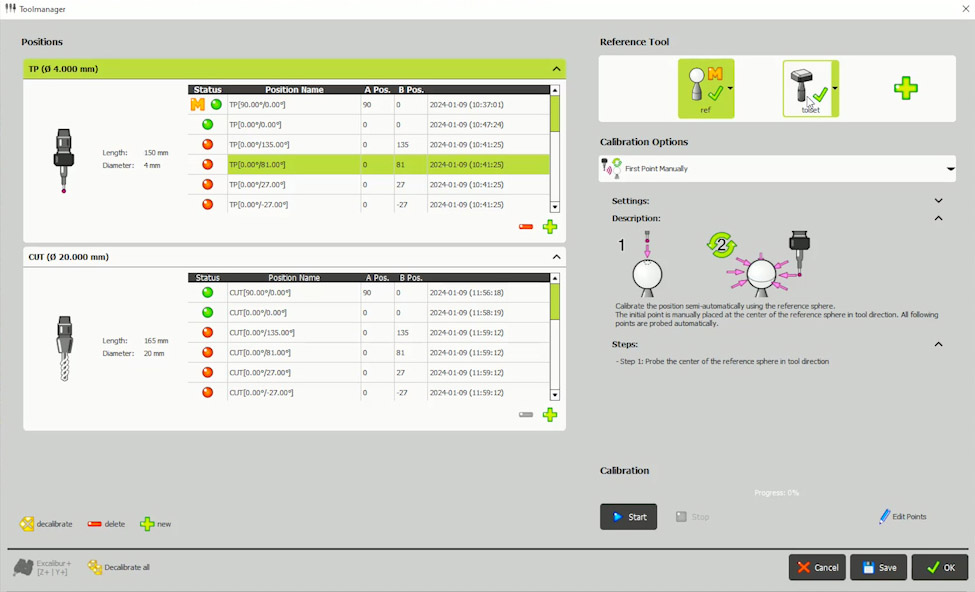

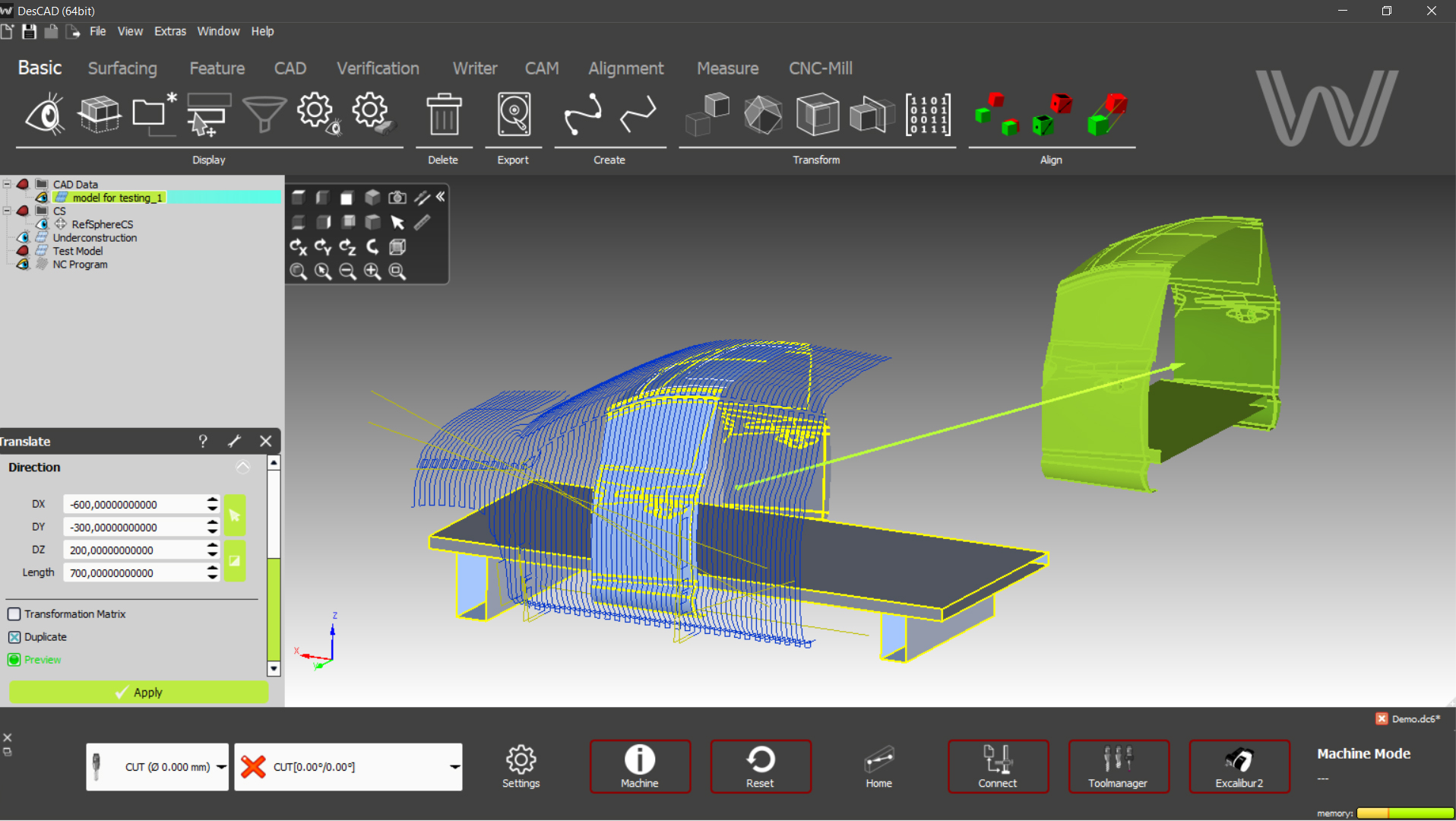

It includes special studio functions which you won´t find in other software. DesCAD let´s you not only create and run your milling files – it also allows you to make easy on-machine changes, provides scanning and layouting functions, has advanced measuring and analysis functions and contains even Reverse Engineering.

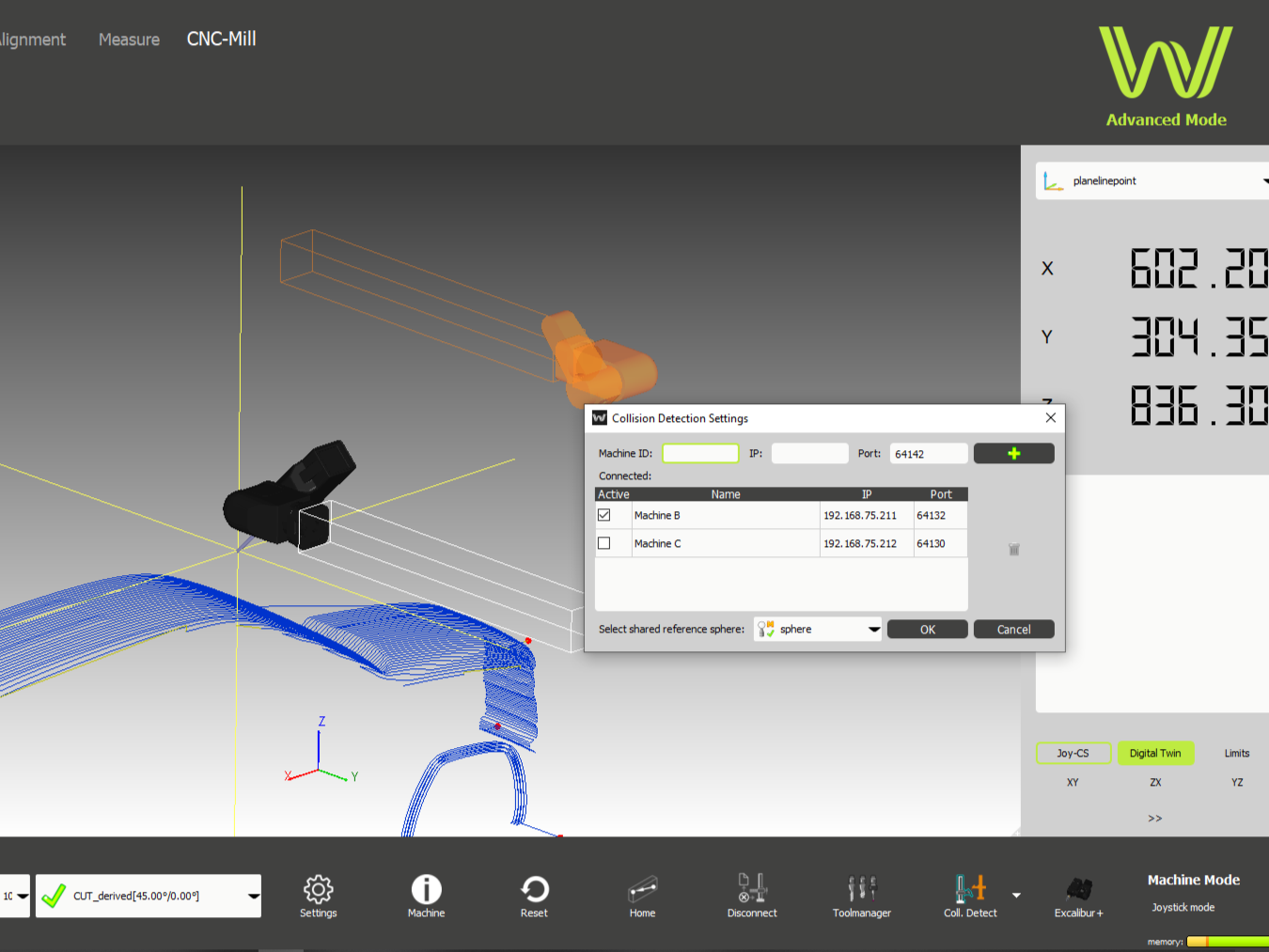

Twice a year we release an update to bring it closer to perfection. The new version 7.4 includes e.g.

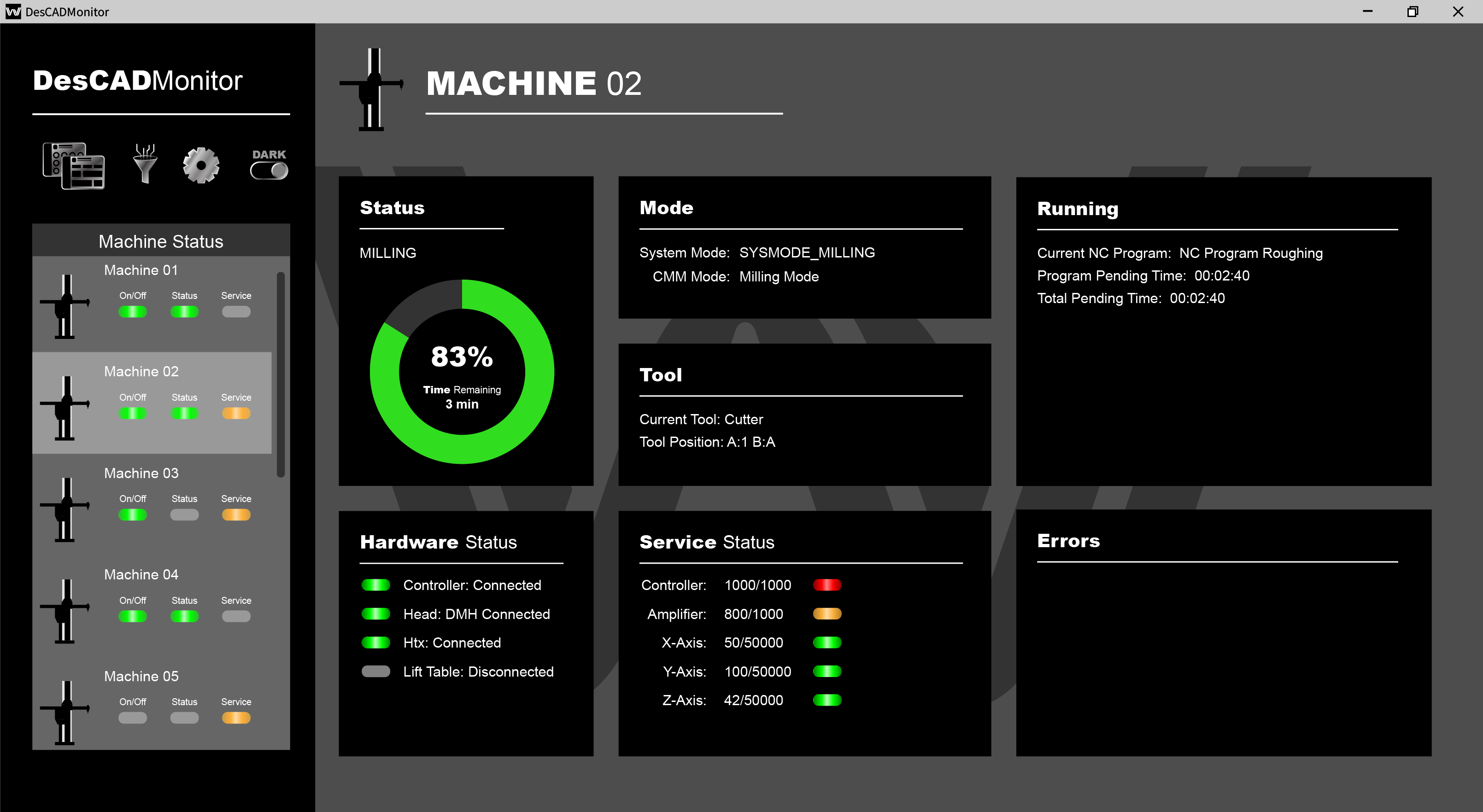

- Enhanced automatic collision detection which protects opposing machines from potential crashes.

- Digital twin shows the current position of the machine and the alignment of the spindle with tool.

- The performance of the DesCAD interface has been significantly improved to make working with it even easier.

- To make it easier to change head modules, the machine brakes can now be accessed directly via checkboxes.

- The installation routine has been extended and now allows the import of settings from existing DesCAD installations.

- The automatic zip function has been extended to include the active CAA compensation file in order to simplify backups.

- The display of the cutter contour when creating NC programs has been removed to further simplify the creation of NC files.

- The size of action windows can now be easily adjusted via the title bar.

- and more…

Get your own personal presentation: contact us!